Code TPWELD

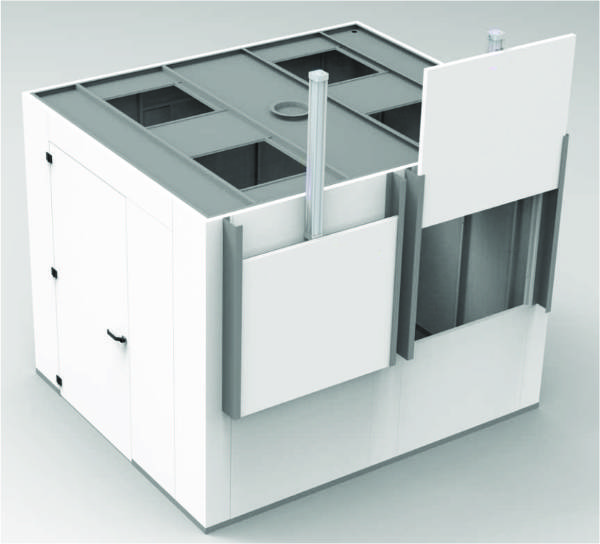

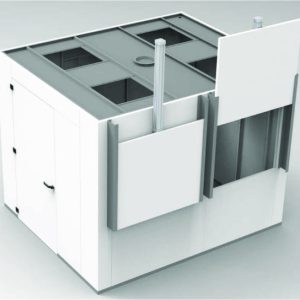

Our cabins are the ideal solution for any production environment that aims to combine efficiency, flexibility, and maximum safety. They are designed according to the strictest international standards and are CE certified, ensuring compliance and reliability.

- Superior Protection and Quality: The cabins are coated with epoxy powders that ensure exceptional durability and resistance over time. Every detail is designed to provide unmatched protection during laser welding processes.

- Modularity and Custom Flexibility: Available in various sizes, TPWeld cabins are modular and scalable. This means they can be customized and expanded simply by adding new panels, perfectly adapting to the customer’s and production’s specific needs.

- Technology and Innovation: They integrate advanced components for optimal control and uncompromising safety.

Each TPWeld laser welding cabin is equipped with a roof and includes all the necessary features for a safe and efficient working environment.

Standard Equipment

- Electrical panel with very low voltage control.

- Signal lamp.

- Lighting kit with LED lamp.

- Cabin power supply via fixed 5-pole 32A plug, three-phase + neutral + ground.

- Inspection window measuring 200x300x3.30 mm, with AC Green glass specific for laser.

- Interlock device for door opening, ensuring maximum safety during operation.

- Painted sheet metal in RAL 7011 as standard. Upon request, painting in any RAL color is available.

- CE marking according to CEI EN 60825-4 Ed. 2007 and CEI EN 60204-1 Ed. 2018 standards.

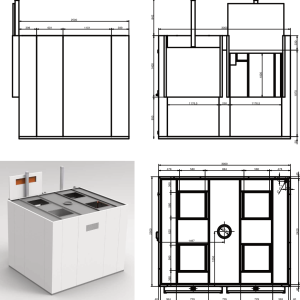

Standard Dimensions

We offer several standard configurations to fit various production spaces:

- 3000 x 4000 x h 2350 mm

- 4000 x 4000 x h 2350 mm

- 6000 x 4000 x h 2350 mm

Please note that the modular design allows the cabin size to be increased, customizing it according to the customer’s specific requirements.