The Importance of Regulatory Compliance in Machine Tool Enclosures

In modern manufacturing, safety and efficiency are two fundamental pillars that support the entire operational structure. Machine tool enclosures play a crucial role in ensuring that both of these elements are respected. This process not only protects operators from potential injuries but also ensures that the machines operate in compliance with current regulations. The machine tool enclosure regulations thus play an essential role in the industry, and their observance is not just a legal requirement but an operational and ethical necessity.

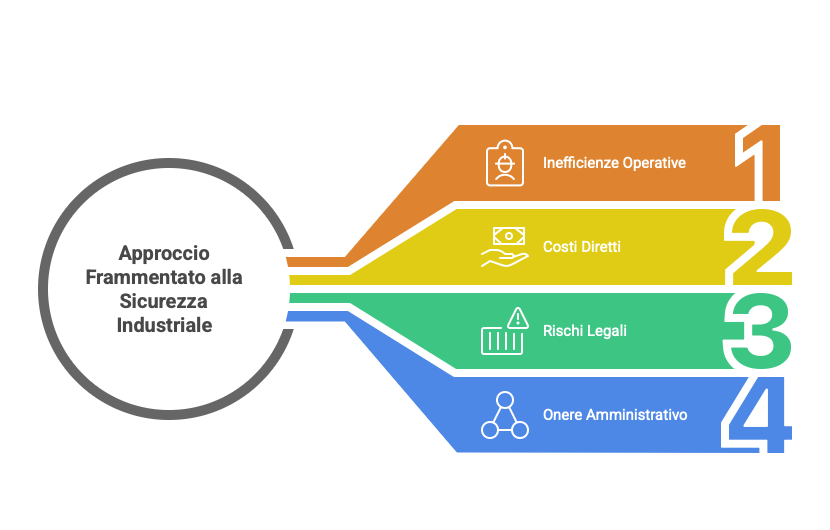

Why Compliance is Crucial

Compliance with directives is not just a bureaucratic formality but a matter of safety and quality. Specific regulations for machine tool enclosures are designed to:

- Prevent Injuries: Enclosures are designed to isolate moving parts and prevent accidental contact that can cause serious injuries.

- Improve Operational Efficiency: Safe machines mean fewer interruptions due to malfunctions or accidents, ensuring greater production efficiency.

- Conform to International Standards: Many regulations are harmonized with international standards, facilitating the export of machines and their acceptance in global markets.

The Regulations: An In-Depth Look

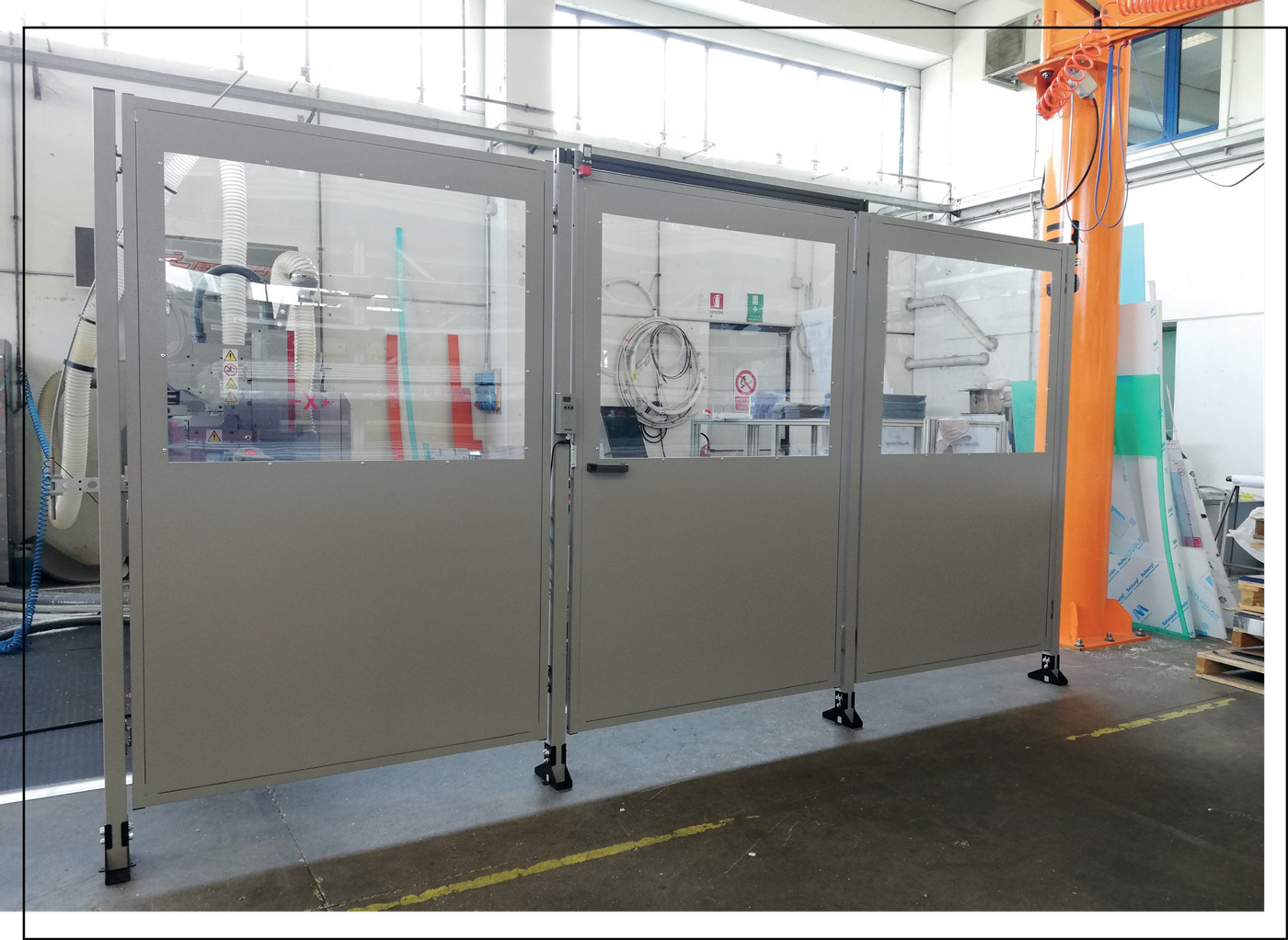

Current regulations cover various aspects of machine tool enclosures, such as the materials used, closure systems, and ease of access for maintenance. A focal point is the UNI EN ISO 14120:2015 standard, which defines general requirements for the design and construction of fixed and movable guards. Following these guidelines not only ensures legal compliance but also elevates the safety standard of the equipment.

Practical Implications of the Regulations

Regulatory compliance requires ongoing commitment to reviewing and updating enclosures. This can involve:

- Periodic Evaluations: Machines must be regularly reviewed to ensure that the machine tool enclosures meet current regulations.

- Personnel Training: Operators must be trained not only in the use of the machines but also in understanding the related safety measures.

- Technological Updates: Adopting new technologies may be necessary to stay in line with the latest regulations.

Ensuring the compliance of machine tool enclosures with current directives is an unavoidable obligation for every company in the sector. This not only guarantees the safety of operators but also strengthens the company’s image as an entity that respects the law and is attentive to the quality of its products. Therefore, machine tool enclosure regulations are not just a legal requirement but a key element for operational excellence and market competitiveness.